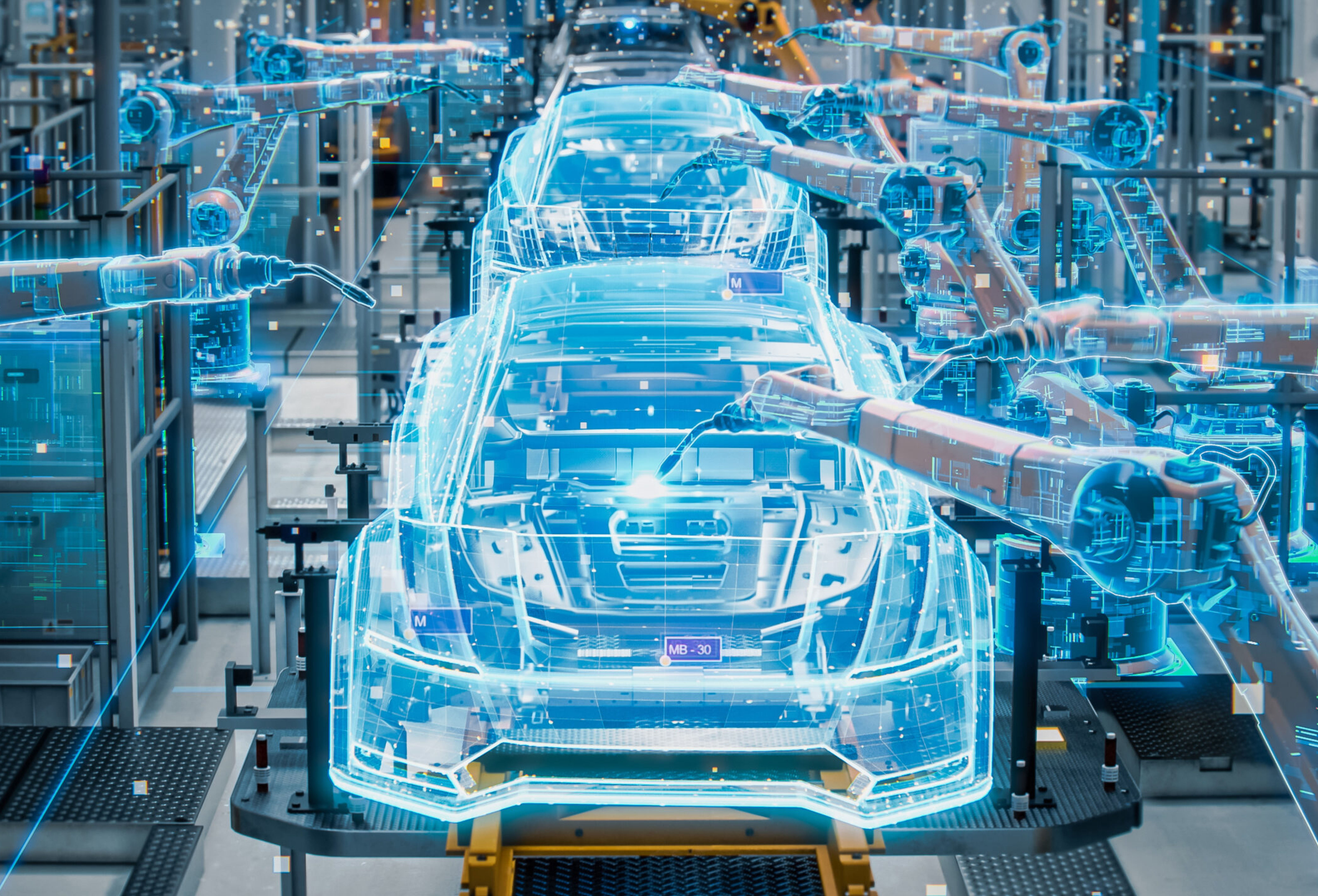

Computer Vision to Drive Quality in Automotive Manufacturing

About Project

Our client, a leading automotive manufacturer, was struggling with quality issues. We collaborated to implement an AI-powered computer vision system with the capability to perform automated quality control. The aim was to achieve high product quality, and more efficiency while reducing time, costs, and other resource utilization associated with manual inspection processes.

Intelligent Watch over Automotive Quality For Complete Assurance

As a leading manufacturer in automotive, our client maintained a super high-volume product line. However, this brought some big challenges in maintaining quality standards. Moreover, till now, they have been relying on manual inspection processes. But this had issues of its own. Not only was it time-consuming, struggling to keep pace with increasing production demands, but also prone to human error again affecting the quality of the products. They needed a mechanized solution that could automate their quality control processes while bringing consistency and reliability to the process and the product.

Automotive Quality Excellence With Smart Computer Vision

01Project Requirements

We needed to develop an AI-enabled computer vision system that could accurately detect defects in real-time. This needed the integration of computer vision algorithms and deep learning models specialized for the automotive domain.

02Project Execution

Our team implemented state-of-the-art computer vision techniques, such as object detection, segmentation, and anomaly detection along with data augmentation and synthetic data generation. We optimized models for real-time inference using edge computing and parallel processing.

03Project Delivery

All of this resulted in high accuracy in defect detection and real-time quality control with low latency. Our solution not only integrated well without disrupting production but could scale with increasing demands and future growth.

Driving Automotive Excellence with AI-Powered Quality Control

Our efforts paid off in the form of significantly improved product quality. The quality-controlling process led to consistent, reliable, and scalable defect detection. We were successful in virtually vanishing the manual errors and the costs associated with it and with rework and warranty claims. Result: high customer satisfaction and brand reputation.

92%

reduction in defects missed during quality inspection

38%

reduction in defects missed during quality inspection

27%

reduction in defects missed during quality inspection

19%

higher customer satisfaction ratings for vehicle quality

How Did We Do it?

Project Challenges

01Data Acquisition and Labeling

02System Integration and Scalability

03Real-time Performance

Power Your Product Quality with AI Vision Solutions